Here at Viking Extrusions, we have been providing the highest quality silicone sponge sheeting for over 30 years. We have a huge range of specifications and grades available, so we can be sure to have what it is you are looking for.

To find out more about the grades of silicone sponge sheet we supply please click the “view product” buttons below to see available sizes, colours, datasheets and certifications for each grade of sheet. Sheeting grades can also be filtered using the search and filter tools in the sidebar to the left.

If you are unsure of which grade of silicone sheet is most suitable for your application, please contact our team of experienced technical advisors who ill be happy to assist with your enquiry.

Silicone is a hugely popular material for a huge variety of different industries and applications. This is because it has a huge amount of benefits that truly help it to stand out amongst other similar materials.

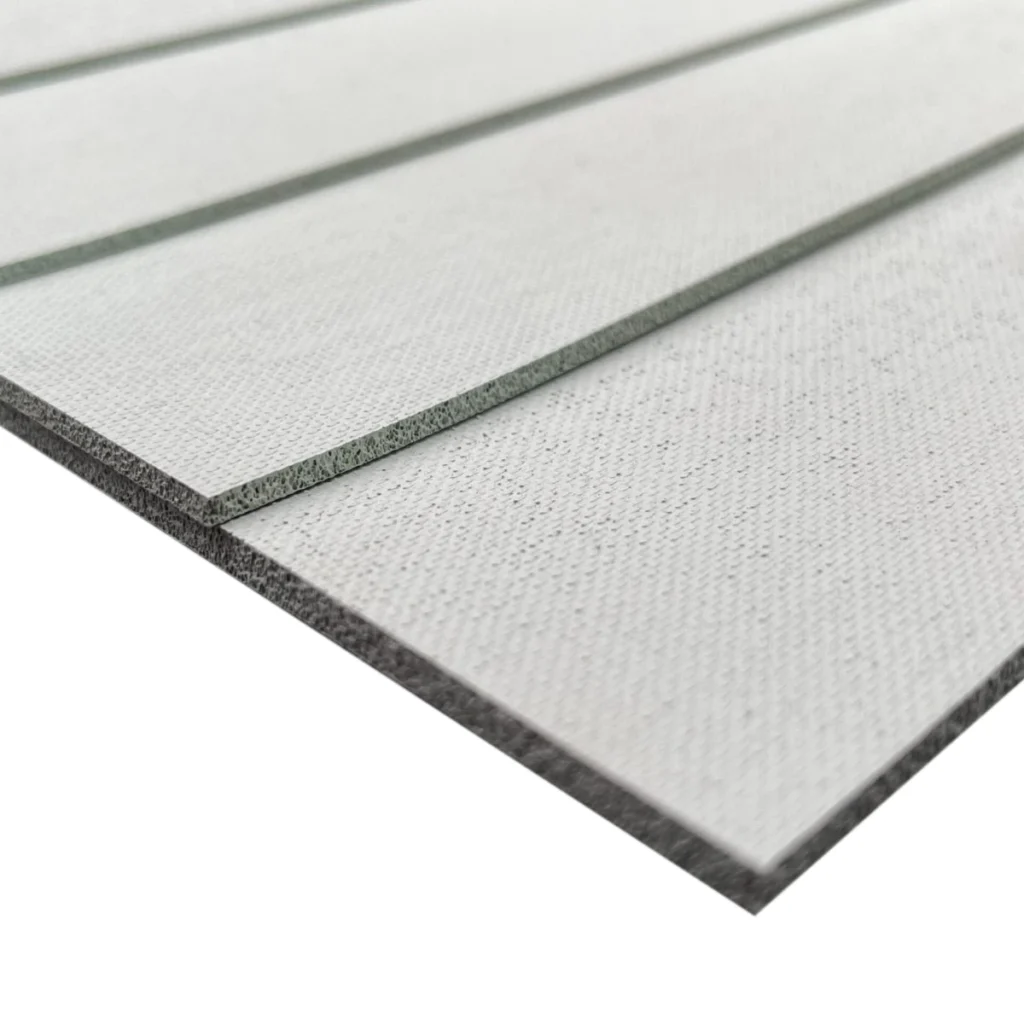

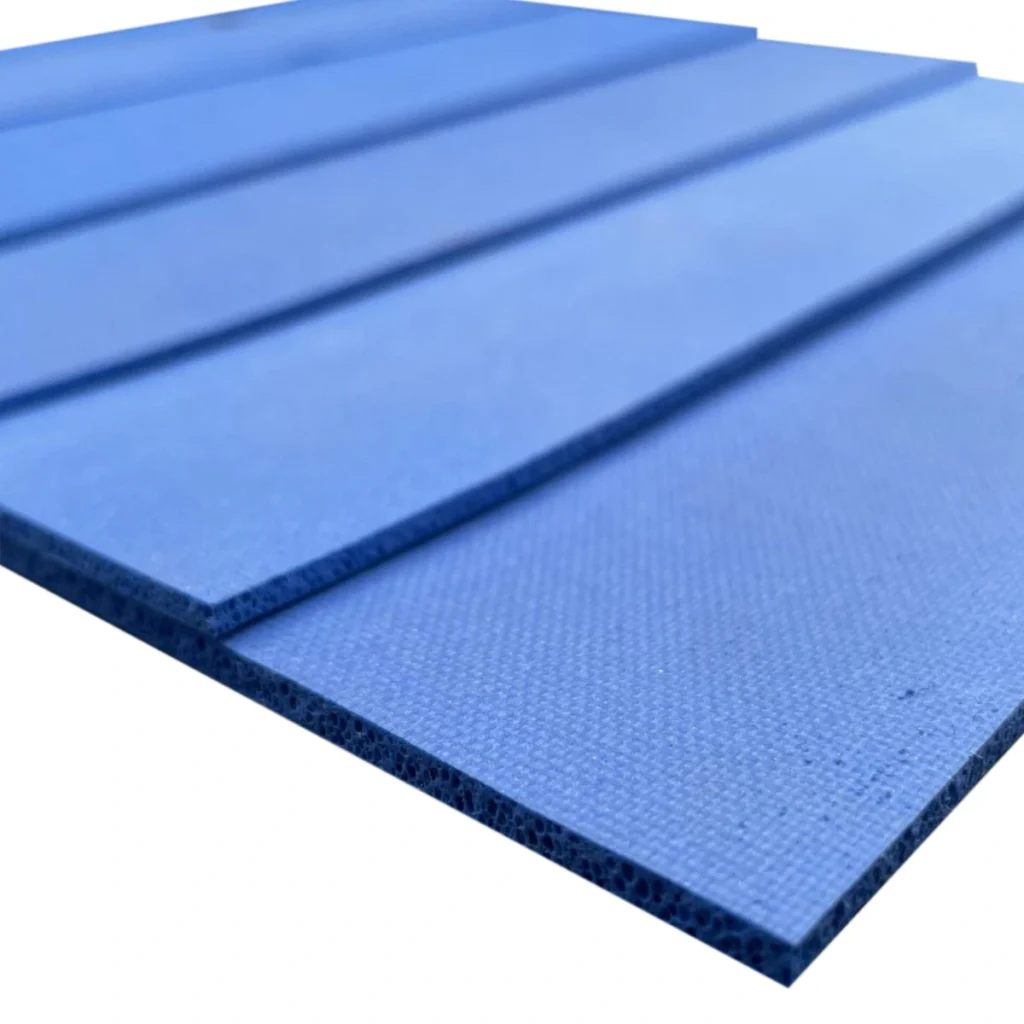

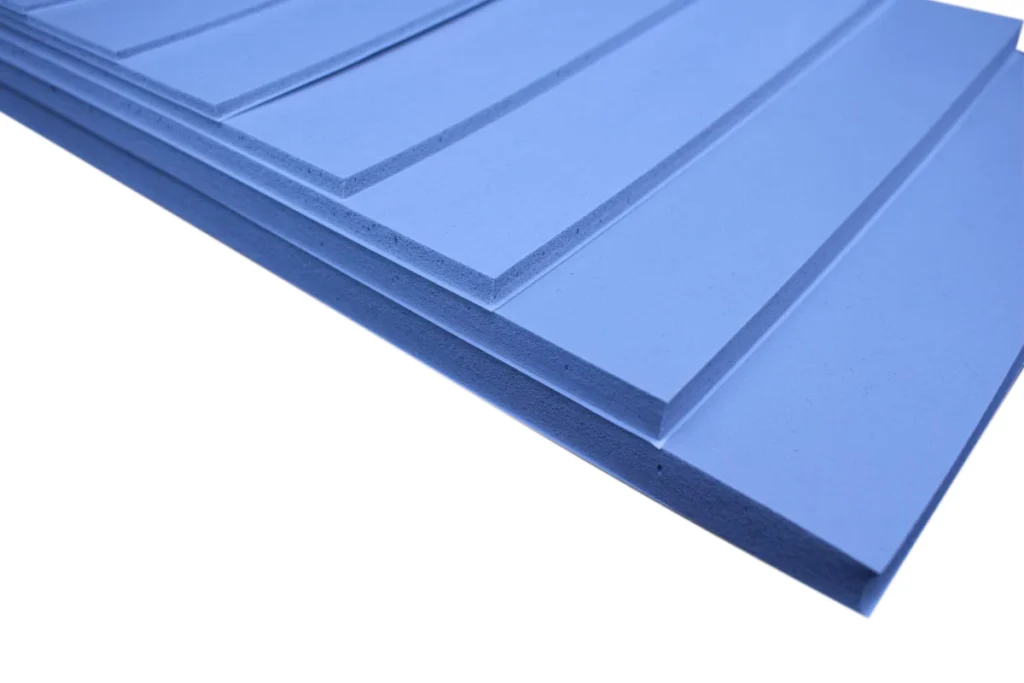

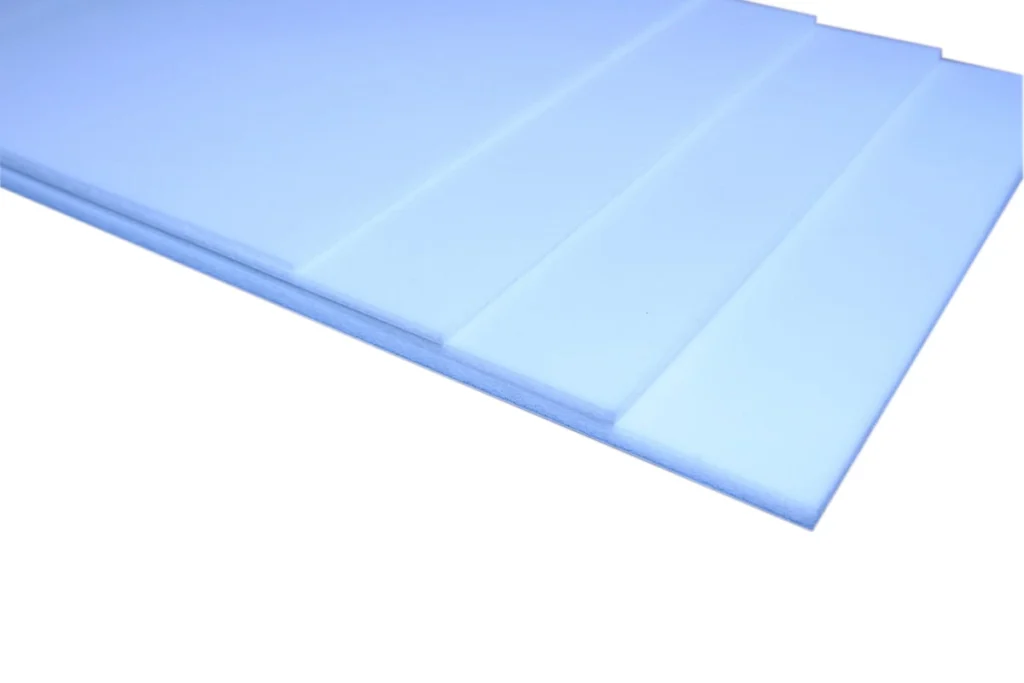

Our silicone sponge sheets are phenomenal, they are amazing for all outdoor applications as they are UV, ozone damage and weather resistant. They are also extremely easy to cut to size, meaning that we can meet your specific requirements with ease.

It is also an amazing thermal insulator and can function at a wide range of temperatures. Its excellent insulation also makes it extremely difficult for liquid or gas to pass through the material’s cellular structure.

With 30 years of experience dealing with silicone products, we truly have mastered the highest quality products. We do not only guarantee the highest quality products, but also customer service. We also pride ourselves on short turnaround times and prices that are sure to beat our competitors.

We can supply silicone sponge sheeting to the following specifications:

Silicone sponge sheet has many advantageous properties including:

Silicone sponge sheeting offers excellent compression properties and is used to produce a variety of gaskets and seals. It is especially useful when sealing surfaces are not smooth. Typical applications for silicone sponge sheeting include:

With open cell sponge, each cell or bubble is openly connected to the next cell. As these cells are not separated water, dust and moisture can make its way through the cell structure.

An example of this would be a commonly used sponge for cleaning, which soaks up water by allowing it to pass through each cell to be held within the sponge.

Closed cell sponge has very different structure to open cell sponge. In a closed cell sponge each cell is a completely closed separated sphere, with air trapped in each cell. The lack of connectivity between cells means that water, dust or moisture cannot readily pass through the cell structure. Closed cell sponge has very low water absorption and is an ideal material choice for sealing applications where water and dust ingress are to be prevented.

The term “sponge” is generally used to describe a closed cell product and the term “foam” for an open cell product.

Silicone foam is a synthetic rubber product that is commonly used in sheets, gasketing and cords. It can be found in solid, cured form or individual liquid components that are used for field applications.

Yes. Silicone sponge is often used for applications that are needing to seal against water, it’s brilliant for this thanks to its water resistant properties.

It is made from a gum based polydimethylsiloxane (PMD). To create the closed sponge structure the polymer is chemically expanded when heated. Closed cell means that the cells are not interconnected and therefore do not allow water to penetrate the sponge.

Contact our expert team of silicone engineers for advice, quotations or any other queries.

Manufacturers of precision silicone rubber extrusions, mouldings and inflatable seals.

© Viking Extrusions. All Rights Reserved.

Designed by Damteq.

Close

We ship our goods worldwide using a variety of couriers including DPD, DHL, TNT, UPS and FEDEX. Please contact us to discuss your shipping requirements.

Close

We ship our goods worldwide using a variety of couriers including DPD, DHL, TNT, UPS and FEDEX. Please contact us to discuss your shipping requirements.