Viking Extrusions are one of Europe’s leading manufacturers of silicone inflatable seals. We have been manufacturing silicone inflatable seals for over 20 years. During this time, we have pioneered many innovative new tooling and manufacturing techniques. Our team have gained a vast amount of experience and technical expertise providing solutions for a diverse range of applications.

On this page…

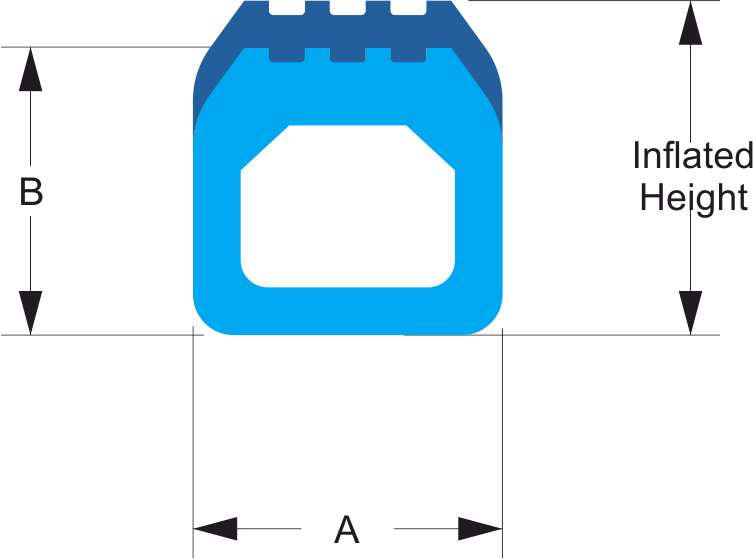

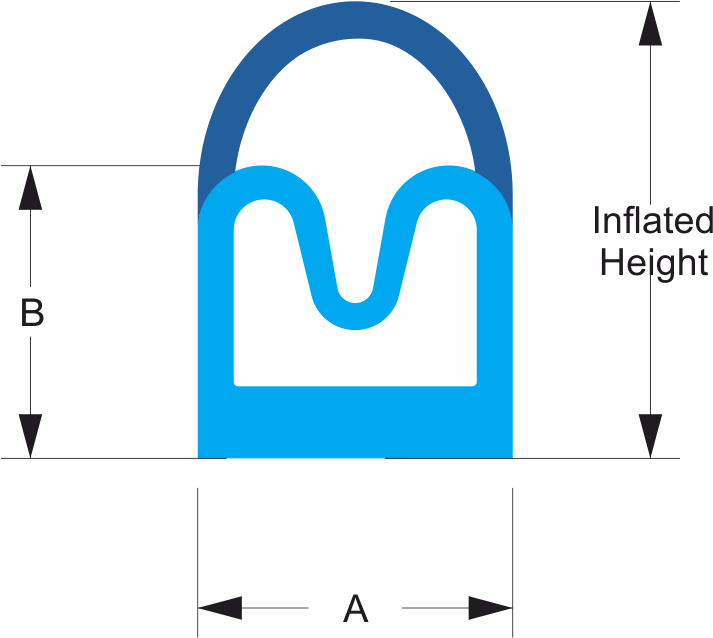

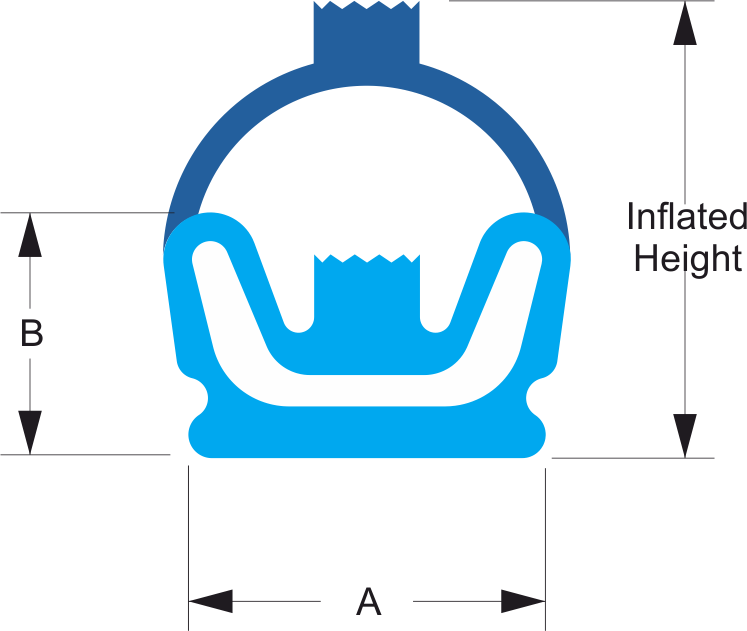

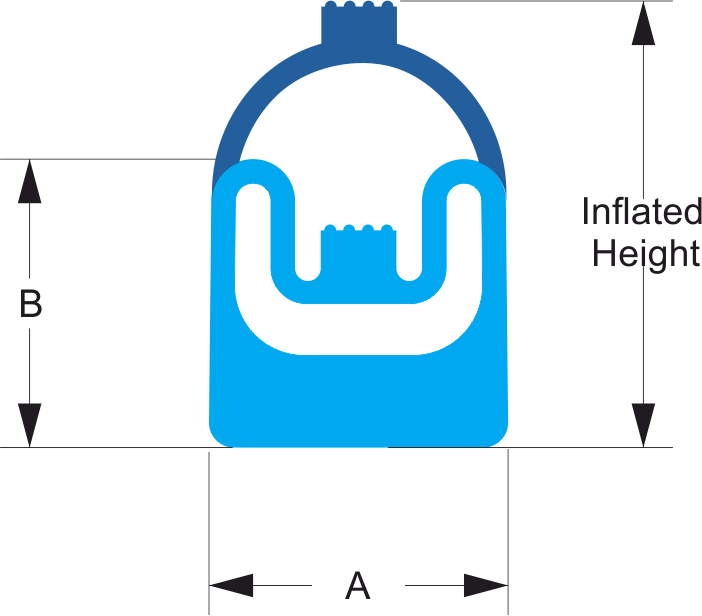

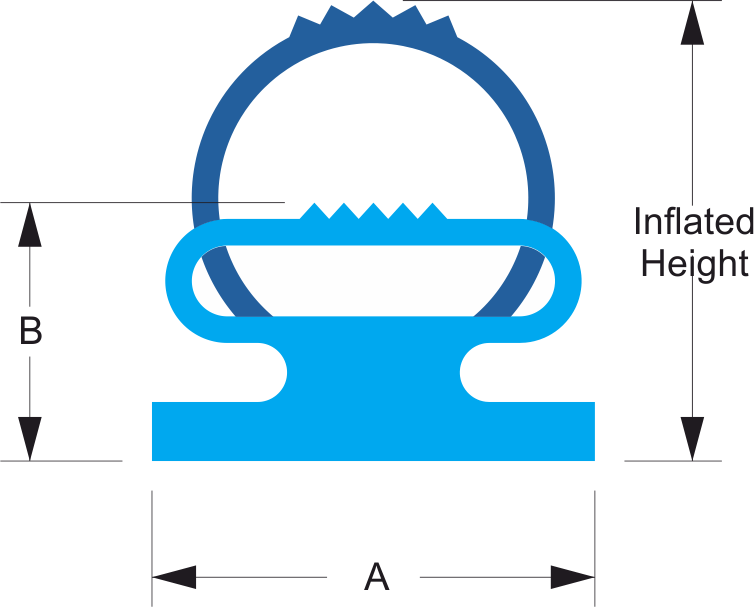

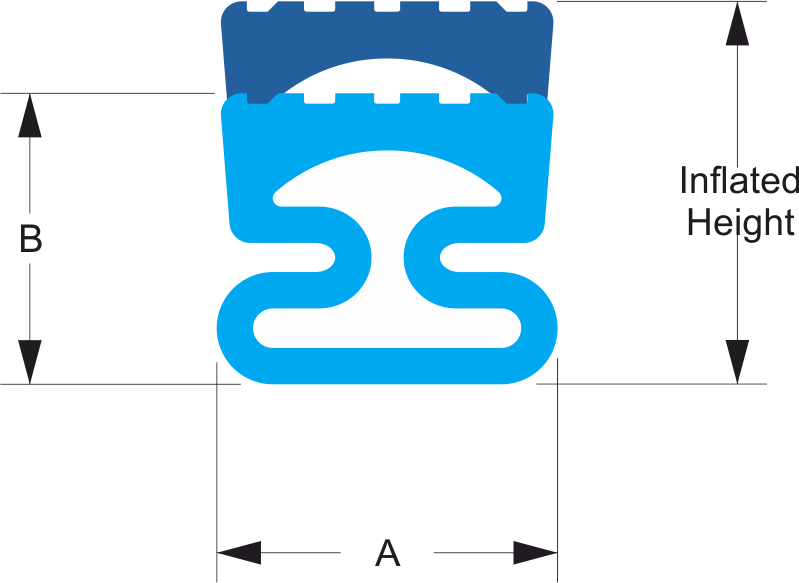

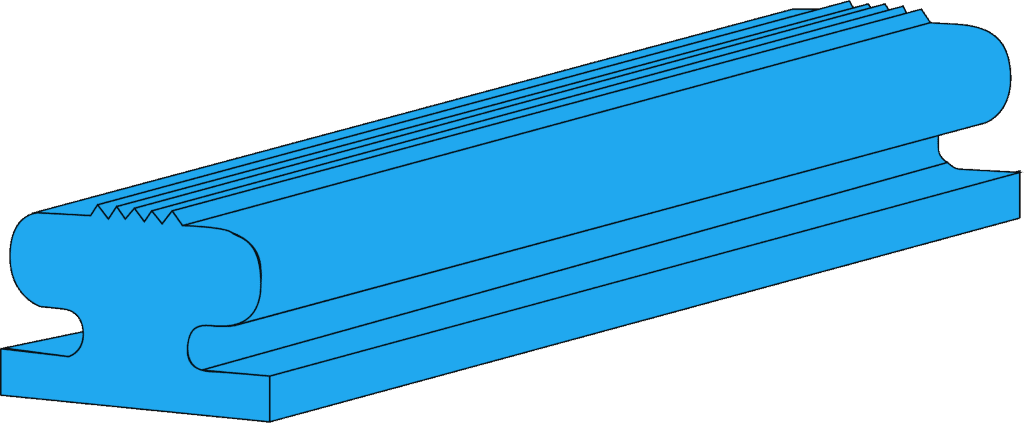

Inflatable seals, also called pneumatic seals or are seals, are made from a hollow extruded profile which is joined into an airtight seal. The seal can then be inflated to form a seal between two surfaces.

We have a large range of existing profiles available for use which can be viewed below. If you require a bespoke solution or a new profile, please contact one of our technical team who will be happy to assist with your project.

Air connectors can be bonded into place, secured with a nut and washer, or with a moulded cone.

Air connectors are most commonly joined to the base of the seal. For some profile shapes it is possible to join air connectors into the side wall of the profile. However, this can have an adverse effect on the seal’s lifespan and durability. For straight length inflatable seals, it is possible to join air connectors into one or both ends of the seal.

Each specific profile design has a minimum bend radius in both its radial and axial planes. Bending a profile below its minimum bend radius will cause it to kink or deform and impair its functionality. For applications where tight radii are required, moulded corners are used to achieve an optimum result.

We are able to design tooling and mould corners for inflatable seals in-house, allowing us to produce high quality seals, at competitive prices and with short lead times, all to bespoke design requirements. If an off-the-shelf solution is required, we have a catalogue of existing mould tools which may be utilised in your design to further reduce costs and lead times.

For advice on moulded corners contact one of our technical team

This compound has been formulated and independently tested to exhibit characteristics such as high tear strength and good joining properties. VINF60 is transparent can be pigmented to most colours. VINF60 is compliant to:

| Property | Value |

|---|---|

| Temperature Range | |

| Appearance | Transparent |

| Density at 20°C | Approx. 1.16g/cm3 |

| Hardness (Shore A) | 60 |

| Tensile Strength | 10.3 N/mm2 |

| Elongation at Break | 524% |

| Tear Strength | 27.5 N/mm |

| Compression Set (22hrs @ 175°C) | 21% |

We can also manufacture inflatable seals from a range of other silicone rubber compounds including high temperature, flame retardant and steam resistant grades.

To view materials and datasheets visit our materials page. For more information on silicone’s chemical compatibility, click here.

Got any questions?

Our team would be delighted to help!

All of our inflatable seals are manufactured at our ISO9001: 2015 certified facility in the UK. Each seal is individually tested by submersion leak tests to ensure it meets the requirements of our quality control system. Every inflatable seal is supplied with a laser etched unique reference number and corresponding signed test certificate. This method ensures consistent quality and full traceability for all of our inflatable seals.

Our inflatable seals are supplied to multiple industries worldwide. They are used for a diverse and ever-growing range of applications from wind tunnels to mega yachts. Some of the industries and applications of our inflatable seals include:

Paper Industry

Suction rollers, scraper bars, cutters

Telecommunications

Semiconductor processing, filters, actuators, scrubbers, robotics, optics

Ship Building

Portholes, lift platforms, loading hatches, drive shaft maintenance.

Textile Industry

Clamping, door seals of pressure chambers

Metalworking

Door seals, scraper bars, continuous steel casting, furnace sealing

Food Industry

Autoclaves, chambers, cutters

Transport

Door seals on high-speed trains, transport containers

Pharmaceuticals

Mixers, robotics, autoclaves, ovens, clean and sterile rooms

See inflatable seals in some of their most common applications.

All videos accessible on our YouTube channel: https://www.youtube.com/@vikingextrusions8112/videos

Mixer lid with moulded corners

Straight length clamp on conveyor

Nuclear airlock door

Bi-folding door

Yacht door seal

Autoclave/steriliser seal

Silicone rubber is an inorganic synthetic elastomer made from a cross-linked silicone-based polymer, offering a unique set of advantageous properties which cannot be matched by other organic elastomers, including:

Variable sealing gap

Inflatable seals are suited to applications where sealing gaps vary. The seal expands to conform around uneven surfaces.

FDA approved

Our inflatable seals are made from FDA and EC1935/2004 certified materials making them suitable for use in food processing applications.

Airtight seal

Silicone inflatable seals can form airtight seals and are used in many medical, pharmaceutical and life sciences applications.

Steam resistant

We are able to manufacture inflatable seals from specialised steam resistant grades of silicone.

Watertight seal

Silicone inflatable seals can form watertight seals making them an ideal choice for a variety of marine applications.

We have a large range of existing profiles available for use which can be viewed below. If you require a bespoke solution or a new profile, please contact one of our technical team who will be happy to assist with your project.

This configuration of seal is well suited to clamping applications as well as shaft maintenance and valve seals. Profile types with large inflating distances relative to their size such as Frog-Leg profiles are generally not well suited to this configuration.

Suitable profile types:

In this configuration, the seal inflates away from its centre. Seals can be clamped into place, fitted into a groove or stretched into place. Common applications for this configuration include airlock door seals and drum/bag filler seals.

Suitable profile types:

Axially configured inflatable seals inflate in the direction perpendicular to the radius of the seal. This configuration is often for door and hatch seals.

Suitable profile types:

By blocking the ends, inflatable seals can be manufactured in straight lengths. These seals are often used in production lines as clamps and actuators, or in civil engineering applications to provide watertight seals under large sliding doors.

Suitable profile types:

By using pre-moulded corners to allow the seal to conform to tight radii, inflatable seals may be manufactured in rectangles. These seals are commonly used on sliding doors and mixer lids.

Suitable profile types:

Goal-Post shaped configurations combine straight length inflatable seals with moulded corners to create a U-shaped seal that expands axially. These seals are used in similar applications to rectangular seals.

Suitable profile types:

Contact our expert team of silicone engineers for advice, quotations or any other queries.

Manufacturers of precision silicone rubber extrusions, mouldings and inflatable seals.

© Viking Extrusions. All Rights Reserved.

Designed by Damteq.

Close

We ship our goods worldwide using a variety of couriers including DPD, DHL, TNT, UPS and FEDEX. Please contact us to discuss your shipping requirements.

Close

We ship our goods worldwide using a variety of couriers including DPD, DHL, TNT, UPS and FEDEX. Please contact us to discuss your shipping requirements.